A Solution for High Temperature Resistance and Zero Leakage - TOYI Series Electric Three Eccentric Hard Seal Butterfly Valves

Release Time:

2023-04-19 17:43

Since ancient times, valve leakage has been a major challenge for engineers. After the emergence of rubber, soft sealing technology enabled most valves to achieve zero leakage. However, fire-resistant valves used in high-temperature environments cannot be sealed with rubber, making high-temperature resistance and zero leakage a natural contradiction.

Since ancient times, valve leakage has been a major challenge for engineers. After the emergence of rubber, soft sealing technology enabled most valves to achieve zero leakage. However, fire-resistant valves used in high-temperature environments cannot be sealed with rubber, making high-temperature resistance and zero leakage a natural contradiction.

In 1966, German engineer Karl Adams registered a patent under the name of "inclined conical seat sealing system", which made a significant progress in butterfly valve technology. In 1967, at the Frankfurt International Chemical Exhibition, a new type of flange eccentric design butterfly valve appeared. This new type of butterfly valve had very high sealing performance and was quickly used in various high-temperature and high-pressure systems. With the unremitting efforts of engineers from various countries, this new type of butterfly valve has gradually developed into a triple eccentric hard seal butterfly valve with a pressure rating of up to 2500 pounds, successfully solving the contradiction between high temperature resistance and zero leakage.

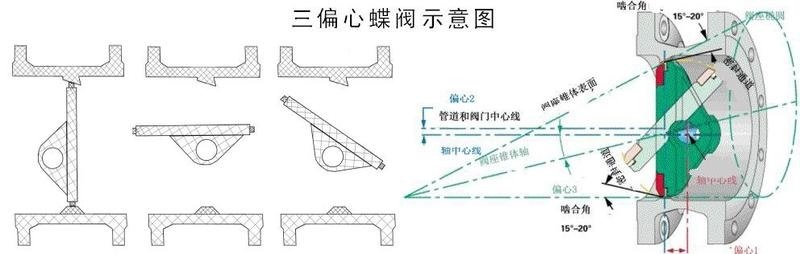

The triple eccentric hard seal butterfly valve is designed to cause the conical axis of the butterfly plate sealing surface to deviate from the cylindrical axis of the body while the double eccentric valve stem axis is eccentric. That is to say, after the third eccentricity, the sealing section of the butterfly plate is no longer a circle, but an ellipse, and the shape of its sealing surface is therefore asymmetric: one side is inclined to the centerline of the body, and the other side is parallel to the centerline of the body. The biggest effect of this third eccentricity is to fundamentally change the sealing structure, no longer position sealing, but torque sealing. In other words, it no longer relies on the elastic deformation of the valve seat, but completely relies on the contact surface pressure of the valve seat to achieve sealing effect. Therefore, the triple eccentric hard seal butterfly valve solves the problem of zero leakage of the metal seat in one go, and the problem of high pressure and high temperature resistance is also easily solved because the contact surface pressure is proportional to the medium pressure.

In the 1980s, triple eccentric hard seal butterfly valves were introduced to China and immediately gained widespread application. Domestic valve manufacturers have also begun to develop such powerful valves, but it is very difficult to achieve zero leakage. In high demand situations, expensive imported valves can only be used. In 1993, Shenzhen Dongyi Electronics Co., Ltd. was established. In order to enable Chinese users to use high-quality electric valves with advanced technology and reasonable prices as soon as possible, Dongyi has collaborated with several well-known domestic valve manufacturers to jointly develop the TOYI series electric three eccentric hard seal butterfly valves, pushing the functionality and quality of domestic valves to a new level.

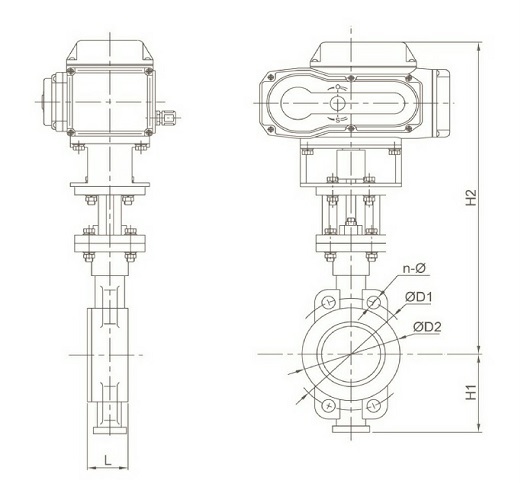

Due to the use of a three eccentric structure, this electric valve has almost no wear on the valve seat and plate, and has a sealing function that tightens as it closes. The sealing ring is made of stainless steel, which has the dual advantages of metal sealing and elastic sealing. It has excellent sealing performance under low pressure and high temperature conditions, as well as corrosion resistance and long service life. The sealing surface of the butterfly plate has a high working strength and is very important, so TOYI adopts overlay welding of cobalt based hard alloy to make the sealing surface more wear-resistant. For ease of installation, this series of valves is also designed with a bidirectional sealing function, which is not limited by the flow direction of the medium or the influence of spatial position during installation, and can be installed in any direction. The drive device can be installed in multiple workstations (rotating 90 ° or 180 °), making it easy for users to use.

After years of unremitting research and improvement by engineers, the performance of TOYI series electric three eccentric hard seal butterfly valves has far exceeded the national GB/T13927-92 valve pressure test standard and received unanimous praise from users. The products are widely used in various high-temperature and high-pressure hazardous areas such as oil and gas exploration, offshore platforms, oil refining, petrochemical, inorganic chemical, energy power generation, etc.

Recommended News